In today’s dynamic and competitive environment, the ability to make quick and accurate data-driven decisions is key to gaining a competitive advantage. That is why Microsoft Fabric—implemented by a Microsoft Partner—provides the most valuable information about production. Using advanced artificial intelligence algorithms, machine learning, and predictive analytics, the platform enables real-time monitoring of production parameters, detection of potential faults and anomalies, and forecasting of future trends.

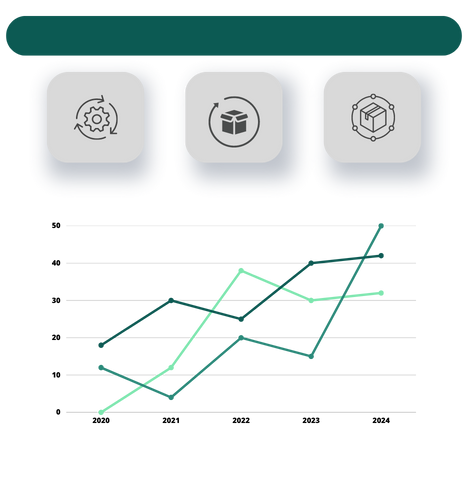

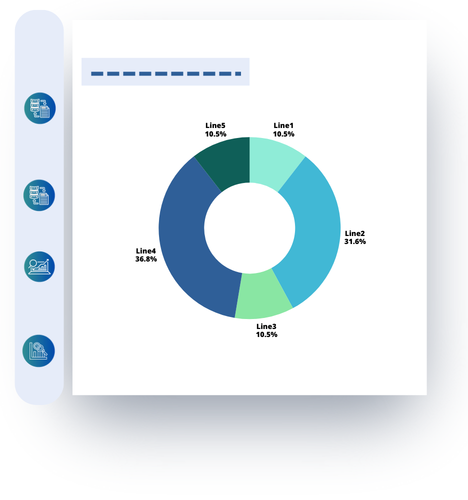

The production hall is a real treasure trove of information that can be successfully exploited. Data such as the number of units produced per day, production costs, the time needed to create a finished product, and the percentage of defective items open the door to a deeper understanding of the processes taking place in the company. With this knowledge, we can make important decisions about productivity and costs in a much more efficient manner.

Analyze data in real time – ask for a quote and take your business to the next level!

Meet Microsoft Fabric - an innovative all-in-one analytics platform that integrates Power BI, Azure Synapse and Azure Data Factory.

Discover how Microsoft Fabric, an advanced analytics platform based on artificial intelligence, is revolutionising data analysis.

The current business market poses many challenges for companies, and one of the key elements for success is the skilful use of available data.

Microsoft Fabric is an advanced tool that revolutionizes data analytics – including real-time analytics, combining various Microsoft services into one comprehensive platform. With a full suite of services, from Power BI to Data Factory, and a Real Time Analytics module, the tool enables companies to respond quickly to changing business conditions. Find out what Real […]

In the dynamic landscape of data-driven decision-making, Microsoft Fabric introduces a game-changing tool – the Data Activator. This no-code experience redefines how businesses automatically respond to evolving data patterns and conditions. Let’s explore how Data Activator revolutionises the business landscape, enabling users to create a digital nervous system that acts across all data sources in […]

In the ever-evolving landscape of data analytics, staying ahead of the curve is crucial for businesses striving to harness the power of information effectively. As we enter 2024, a new era of data analytics unfolds, promising innovative methodologies and cutting-edge tools. Let’s delve into the five emerging trends shaping the data analytics landscape and explore […]

In today’s dynamic business landscape, harnessing the full potential of data is no longer a luxury but a necessity. As organisations grapple with vast amounts of data from diverse sources, having a comprehensive tool that seamlessly integrates various services becomes paramount. Enter Microsoft Fabric – a revolutionary platform that converges data lake, data engineering, data […]

In business analytics and data processing, Microsoft has implemented several tools that effectively respond to the diverse needs of companies. Despite the long-standing popularity of the Power BI service among business users across various sectors, Microsoft’s new platform, Fabric, has ambitions to gain even more market share. What is the difference between Microsoft Fabric and […]